Uranium in Seawater

Overview of Research

This project active from 2014 to 2018 built upon the efforts within the DOE's Fuel Cycle Research and Development program by offering infrastructure and expertise for marine testing of an adsorbent fiber designed specifically to extract uranium from seawater. We are testing the fibers in the lab and ocean to quantify sorptive properties and uranium uptake in real ocean conditions. There is currently a gap between detailed lab studies and potential large-scale applications of these technologies. To fill this gap our group has tested fibers under varying flow conditions using filtered seawater as well as dock testing in a coastal ocean environment. We tested biofouling mitigation techniques by using copper, steel or nylon enclosures on the dock in fall 2015. In fall 2016 we tested the reuse of the fibers after deployment in the ocean. Lastly as a collaboration with A. Slocum at MIT and PhD student Maha Haji we examined the effect of enclosures on the fiber adsorption as well as explored deploying the fibers on a engineered system that would couple with a wind turbine platform.

This project active from 2014 to 2018 built upon the efforts within the DOE's Fuel Cycle Research and Development program by offering infrastructure and expertise for marine testing of an adsorbent fiber designed specifically to extract uranium from seawater. We are testing the fibers in the lab and ocean to quantify sorptive properties and uranium uptake in real ocean conditions. There is currently a gap between detailed lab studies and potential large-scale applications of these technologies. To fill this gap our group has tested fibers under varying flow conditions using filtered seawater as well as dock testing in a coastal ocean environment. We tested biofouling mitigation techniques by using copper, steel or nylon enclosures on the dock in fall 2015. In fall 2016 we tested the reuse of the fibers after deployment in the ocean. Lastly as a collaboration with A. Slocum at MIT and PhD student Maha Haji we examined the effect of enclosures on the fiber adsorption as well as explored deploying the fibers on a engineered system that would couple with a wind turbine platform.

Our objectives were as follows:

- To test the extraction efficiency of the uranium adsorbents under changing environmental conditions (temperature, flow rate, salinity, particulate matter) in a controlled laboratory setting and in the ocean

- To determine, by field tests, the most efficient methods for collecting (pumping versus passive) and the best platform (mooring type, sorbent material) to expose the fibers in high current regimes.

- To design a mooring contingent on the findings in objective 2 that will be amenable to scaling up small batch extraction of uranium from seawater using these new large volume in-situ methods.

Results of Ocean Testing

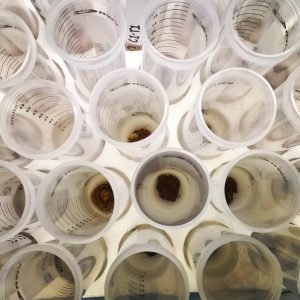

Details regarding methods used for this project can be found in both the forthcoming paper Drysdale et al. (2019) or in the project reports linked below. Overall we tested the amidoxime-based polymer type AI8 developed at Oak Ridge National Laboratory (DOE). Fibers were deployed in a variety of experiments to test the effects of biofouling or reusing the fibers.

Overall fibers were negatively affected by biofouling, where uranium adsorption was reduced by up to 70% on fouled fibers. Increased temperatures allowed for increased uranium adsorption, but also increased the amount of creatures that grew on the fibers. There is a delicate balance to be found between optimal temperature and one at which the biofouling does not interfere substantially on uranium uptake. Reusing the fibers was not found to be particularly effective as the total harvestable uranium after a single 56 day deployment was comparable to that of fibers deployed 2 or 3 times over 84 days.

Testing Fiber Enclosures

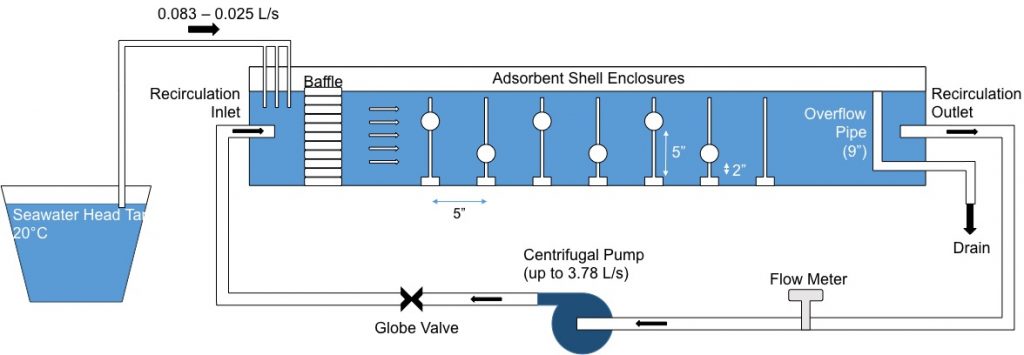

Working with Dr. Haji, Dr. Slocum and student J. Gonzalez from MIT we facilitated testing how fiber enclosures affect the adsorption of uranium from seawater in a flume. This experiment tested 6 different wiffle-ball like enclosures, plus one fiber not enclosed. These were fastened in a high velocity flume (4.8 m/s flow) and tested every 7 days for 56 days.

It was found that at the flow rate used the shell enclosure had no definitive effect on uranium uptake and that they all had relatively high uptake compared to the ocean studies. More information can be found in the paper written on this topic here.

Diagram of the flume setup used to test the adsorbent enclosures. Fresh seawater is pumped in using three tubes near the recirculation inlet. Overflow pipe ensures a constant water level of 9”. A Finish Thompson DB8 Centrifugal Pump constantly recirculates the filtered seawater. (graphic by Jorge Gonzalez)

Coupling Uranium Extraction With Wind Turbines

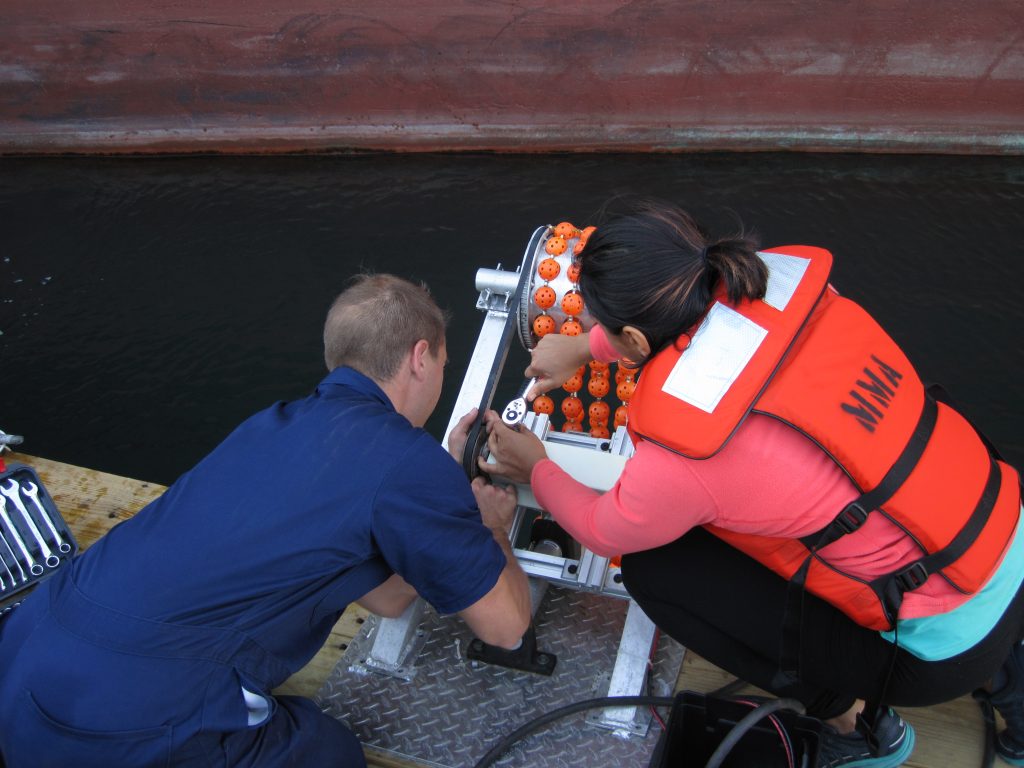

Current deployment schemes for uranium adsorbing fibers are stand-alone systems that have significant practical challenges. We worked with Maha Haji to test the Symbiotic Machine for Ocean uRanium Extraction (SMORE). This system pairs an existing offshore structure with the fiber adsorption by using a shell enclosure. The enclosure can either move continuously or be stationary. Overall ocean testing was inconclusive as to whether movement aided in adsorption at the velocities tested. The system does allow for the incorporation of other design elements to further mitigate biofouling or to desorb uranium if fibers are to be reused. Further information on this research is available in the published paper Haji et al., 2019.

Final Project Report

There are a lot of reports for DOE projects - here is our FINAL one for this project available to download: DE-NE000713 Final Report

Funding Agencies

This project was funded through the U.S. Department of Energy Office of Nuclear Energy's Nuclear Energy University Program (Contract DE-NE000713, Project #13-4905).

Research Papers

- Drysdale, J.A. & Buesseler, K.O. (2020) Uranium adsorption behaviour of amidoximated fibers under coastal ocean conditions. Progress in Nuclear Energy,119, Art 103170. DOI: 10.1016/j.pnucene.2019.103170

- Haji, M.N., Drysdale, J.D., Buesseler, K.O., Slocum, A.H. (2019) Results of an ocean trial of the symbiotic machine for ocean uranium extraction. Environmental Science and Technology, 53(4), 2229-2237.

- Haji, M.N., Gonzalez, J., Drysdale, J.A., Buesseler, K.O., Slocum, A.H. (2018) Effects of protective shell enclosures on uranium adsorbing polymers. Industrial & Engineering Chemistry Research, 57, 15534-15541.

- Gill, G. et al. including K. Buesseler, C. Breier (2016). The Uranium from Seawater Program at PNNL: Overview of Marine Testing, Adsorbent Characterization, Adsorbent Durability, Adsorbent Toxicity, and Deployment Studies. Industrial & Engineering Chemistry Research, 55(15), 4264-4277. DOI: 10.1021/acs.iecr.5b03649.